Frequently Asked Questions

Installation Suggestions

What exactly do you mean by "Sawblade Deviation?"

When either a bandsaw or circular saw is properly set up and properly operated, the blade will consistently run in exactly the same position. If the blade moves away from that set postion, that is called blade deviation. The AccuraCut Deviation Detector will help you spot that deviation from expected position as the cut is occurring so that you can take corrective action immediately.

How does the unit know where the blade is? Does it actually touch the blade?

No, part of the unit comes in direct contact with the blade. The system measures the position of the blade by noting its effect on a pulsating electromagnetic field. This way, it "sees" only the blade itself and is not affected by word chips, cutting fluid, or any other non-metallic substance between the blade and the detector.

What does the system consist of? What comes with the complete unit?

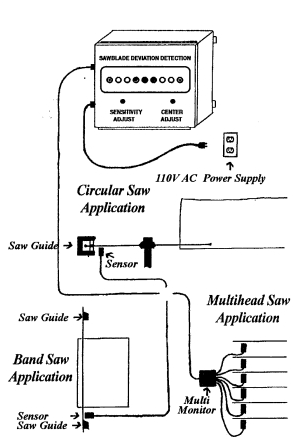

There are three main components to the complete system: the sensor, which is a small cylindrical object mounted near the blade; a controller display unit which is typically mounted in the sawyer's cab; and a data cable which connects the other two components together. We also provide a small bracket for mounting the sensor and (optionally) any extra cable needed to extend the distance from the sensor ro the controller/display unit.

What kind of conditions will cause blade deviation?

The most common cause of blade deviation is improper feed speed - feeding lumber into the saw at a rate higher than the blade can handle forces the blade out of position. Damage to the blade (caused perhaps by hitting trash in the wood) can result in an uneven set on the blade teeth, causing the blade to pull to the side on each cut. Cutting frozen or heavily knotted wood requires reduced feed speeds to ensure a proper cut. Worn or damaged blade guides can cause the blade position to shift. The important thing is that no matter what the cause, if the blade's position changes, the saw operator will see that change immediately on the operator's monitoring display panel.

What exactly is that output? What will the operator see?

The controller display unit, which is normally mounted in the saw operator's line of sight within the saw cab, is equipped with a row of 9 colored, highly visible lights. The three center lights are green, indicating the normal operating range. Four more lights, two on either side of the green lights, are orange, indicating significant levels of deviation. On each end of the row are single red lights indicating maximum deviation. Only one light is illuminated at any time. The illuminated light's position with respect to the center indicates the direction and degree of the blade deviation that is occurring. The unit contains an audible alarm which can be seen to go off whenever maximum deviation occurs. That same signal can be fed to an optional external relay which can be used to trigger a strobe light., external alarm, or shut-down switch.

Can the deviation output be recorded or remotely monitored?

Yes. An optional remote light set can be connected to a special output port on the side of the unit. These lights can be placed in the maintenance room, filing room, or other location and will exactly mimic the main lights on the controller display unit. There is also another output port on the AccuraCut which provides an analog signal proportional to deviation which can be recorded on an oscilloscope or strip chart recorder for later analysis.

Can the output signal be used to automatically control feed speed?

Automatic control of the carriage would require special interface electronics which depend on the type of carriage mechanism and speed controller being used. Call for pricing.

How difficult is it to intall the AccuraCut Deviator? Will I need help?

In most cases, installation of the AccuraCut Deviation Detector is very straight forward and can be handled by your own in-house maintenance personnel. You simply mount the sensor near the blade either just below the upper guide, or just above the lower guide; install the controller display unit in the sawyer's cab and connect it to 110V input power. You then connect the two components using the cable provided. On-site installation is available. Call to schedule Jeff Miller Inc. service.

Will this system work for any width of blade?

Because of the size of the sensor itself, it isn't recommended for blades narrower than 1" in width. However, wider blades should present no problem as long as the sensor is properly mounted.

Do I mount the sensor in the center of the blade or near the edge? What do I do if I have a double cut bandsaw in both directions?

Since it is the movement of the leading edge of the blade which is most critical, normally the sensor is mounted just behind the gullet and about 1/4" away from the surface of the blade. However, for double cut application, mount the sensor in the center of the blade to get useful information. For optimum performance on wide blades in a double cut application, we recommend using two systems with a detector mounted on each edge of the blade. This will give uncompromised information about the performance of the blade in each direction and allow independent adjustment of the system parameters for each direction of cut.

What sort of set-up adjustments are required?

The body of the sensor unit is threaded and is secured by a large nut on either side of the mounting bracket. While the blade is stationary, you attach the sensor to the bracket and adjust it's position with the nuts until only the center green light is illuminated on the display unit. Once the saw is in operation, you can fine tune the centering of the lights (to compensate for guide wear, etc.) through an electronic control on the face of the controller unit. You can also adjust the response rate (how quickly the lights react to changes) through another control knob on the unit. This gives you the option to look at every tiny flicker in the blade's position or to filter out the high frequency effects and just concentrate on the longer term movement of the blade.

Just how sensitive is the unit anyway? What is the smallest deviation I can detect?

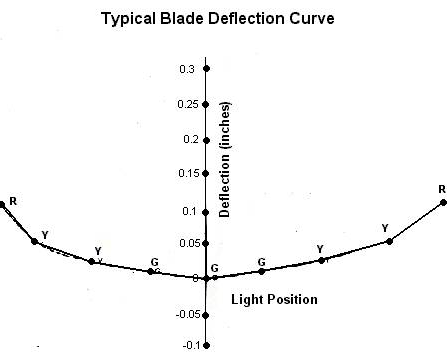

The unit itself is very sensitive and can measure deviations of only a few thousandths of an inch. However, the actual movement of the blade at the point of cut will depend on the geometry of the installation since the sensor will always be some distance away from the point of cut. How far the sensor is from the cut and how far it is from the blade guide will determine the relative deviation being measured. Since this is different for every installation, we recommend you measure this as part of the set-up process. While the saw is stationary and after the sensor has been installed and adjusted, simply deflect the blade at a position representing the point of cut and measure the amount of deflection while noting the response of the lights over the full range. In order to provide the maximum useful range, the output is electronically adjusted to give more response in the center green light region where it's most critical. The amount of deviation represented by each light grows greater as you move further out toward the limit on each side.